Philips is a comprehensive electronics manufacturer from the Netherlands. It began in 1891 in Eindhoven, in the southern part of the Netherlands, with the production of incandescent light bulbs. In Japan, Philips is known for household appliances such as shavers and coffee makers, but its business pillars also include laser technology for CDs and Blu-ray discs, as well as medical equipment. Of course, the lighting business was the beginning and core business of Philips. Until recently, the company's official name was "Philips Incandescent Lamp Works." It is now known as Royal Philips Electronics. In 2001, the Dutch royal family granted the company the title "Royal," and it became Royal Philips Electronics. In the same year, the headquarters moved from Eindhoven to Amsterdam.

■The generator of the bicycle light called Philidyne and the cabinet resin material of the radio called Philite were used to create PHILIPS' electric shaver, PHILISHAVE

In 1907, Belgian scientist Leo Baekeland invented the synthetic resin known as Bakelite, the world's first synthetic resin. In 1923, Philips started operating a factory to mold this Bakelite resin, producing radio parts and electrical components. However, the name "Bakelite" was globally trademarked by the Bakelite Corporation, so Philips registered "Philite" as a trademark in 1930 and widely used it for Philips molded products. The Philips Philite factory was the largest plastic molding factory in the Netherlands until around 1940. In 1967, it merged with Philips Metal Works, initially named Philite and Metal Products Factory, later becoming Plastics and Metal Products Factory (PMF), and the name Philite disappeared. Philite required high temperatures and pressures, and continuous operation was necessary to increase production efficiency. Therefore, radio parts and radio cabinets alone could not meet production capacity, and various daily items were molded. Philite-made speakers, cups, plates, bowls, and ashtrays are still treasured as collectible items. Many daily items were molded from Philite even after the war, including toilet seats.

When the prototype head of the Philishave, using the housing of the Zephyr Shaver, was disassembled, both the cutter and cutter guard were almost ready for mass production.

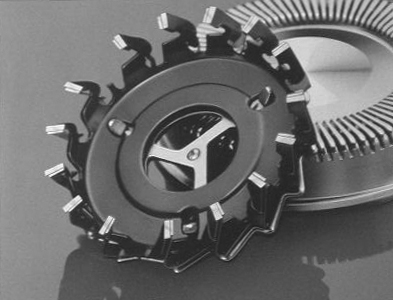

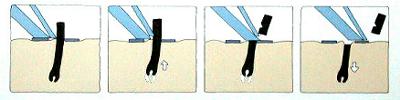

Philips' second-largest business, radio, was skewed towards the autumn season (with the Christmas season being the biggest opportunity), so developing items that could be sold year-round was urgent, and efficient operation of the Philite resin molding factory was essential. To overcome the global depression, new products were needed, and a plan to develop a third item was launched. Electric shavers were cutting-edge household appliances at the time, but the idea of making electric shavers was initially met with skepticism by then-president Anton Philips, who reportedly asked, "Are we becoming barbers?" Initially, there was an option to import and sell the latest electric shavers from the advanced US market, so a representative was sent to the US to conduct market and product research, bringing back a suitcase full of the latest electric shavers. The technical department was asked to investigate these electric shavers, and Alexander Horowitz began to think about whether a faster and safer "shaving" method could be developed. He believed that if a straight blade could be made circular, it would capture hair from all directions, significantly improving shaving efficiency, and that rotary motion would allow continuous cutting without interruption (unlike reciprocating motion, which always stops at both ends of the stroke). He created a prototype with an cutter guard with 48 grooves and an cutter rotating at 10,000 rpm. Based on this, development funds were officially allocated, and Model 7730 was born. However, while there was still internal debate about whether to officially produce it, even Gillette, the top brand of safety razors in the largest market, the US, released an electric shaver. It is said that Philips officially gave the go-ahead for the shaver project in March 1938. The goal was to have it ready for the "Spring Exhibition" in Utrecht in March 1939. The first PHILISHAVE Model 7730 left the production line just a week before the Spring Exhibition on March 9, 1939.

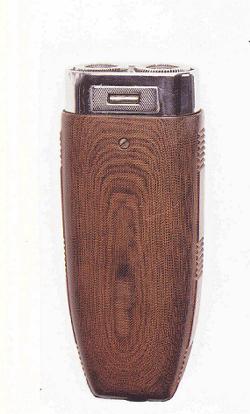

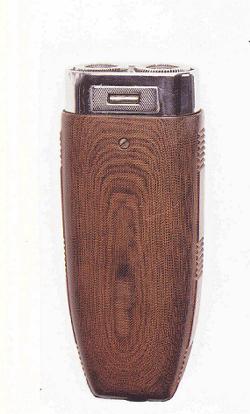

The working sample housing of the Two Header Shaver was made of wood.

Six prototypes of two header model were completed during the war, but they were kept top secret until the end of the war, and the actual release was the 1951 Model 7743. Why did it take so long? Naturally, the Two Header required twice as many blades to produce the same number of shavers, necessitating increased production of shaving heads. In 1950, Drachten in northern Netherlands was chosen from three candidate sites for a new factory.This factory became the center of Philishave development to this day.

Until the Drachten shaver factory was built, radio factory engineers were also responsible for shaver development. Rather, all development seemed to be concentrated in the headquarters development department, and the Two Header was conceived by two engineers from the headquarters design department (Lex Van Dam and Appie van der Lee). The development of the Two Header was not an official project but emerged from the independent activities of these two engineers. With the cooperation of other departments, they completed the working sample, reported it to their superiors, who then reported it to management. They were formally granted permission to produce six working samples, but the details were kept top secret until the end of the war to prevent them from being used by the occupying Nazi forces. Additionally, wartime material controls led to shortages of materials for civilian products, resulting in lower production scales.

American manufacturers had already entered the era of multiple heads before the war (1940s), but Philishave only released the Two Header after the war. The full-scale production of multi-head Philishave began after the Drachten factory started operations, several years after the war. Compared to war-torn Europe, America was the largest market at the time. Philips began activities in America in the 1930s and released the first Model 7730.

In the early 1940s, the American company PHILCO registered "Philips" as a trademark due to the similarity in sound. Unable to use the company name "Philips," they used the initials of North American Philips [Electrical] Company to create the brand "Norelco," which continues to this day. The first shaver officially launched under the Norelco brand was the 1948 "IVORY." In 1951, they introduced the Double Header to the American market, but it was not very successful. A few years later, they renamed the same model "Speedshave," which significantly increased recognition and market share. Subsequently, they adopted new models and features such as the "Floating Head," "Flip-top Head," and the Three Header, focusing advertising on the Christmas sales season to increase market share. Recently, some products have used the Philips brand, but most Americans still think of Norelco as an American shaver, indicating how deeply it has penetrated the American market.

In the early 1940s, the American company PHILCO registered "Philips" as a trademark due to the similarity in sound. Unable to use the company name "Philips," they used the initials of North American Philips [Electrical] Company to create the brand "Norelco," which continues to this day. The first shaver officially launched under the Norelco brand was the 1948 "IVORY." In 1951, they introduced the Double Header to the American market, but it was not very successful. A few years later, they renamed the same model "Speedshave," which significantly increased recognition and market share. Subsequently, they adopted new models and features such as the "Floating Head," "Flip-top Head," and the Three Header, focusing advertising on the Christmas sales season to increase market share. Recently, some products have used the Philips brand, but most Americans still think of Norelco as an American shaver, indicating how deeply it has penetrated the American market.

In the early 1940s, the American company PHILCO registered "Philips" as a trademark due to the similarity in sound. Unable to use the company name "Philips," they used the initials of North American Philips [Electrical] Company to create the brand "Norelco," which continues to this day. The first shaver officially launched under the Norelco brand was the 1948 "IVORY." In 1951, they introduced the Double Header to the American market, but it was not very successful. A few years later, they renamed the same model "Speedshave," which significantly increased recognition and market share. Subsequently, they adopted new models and features such as the "Floating Head," "Flip-top Head," and the Three Header, focusing advertising on the Christmas sales season to increase market share. Recently, some products have used the Philips brand, but most Americans still think of Norelco as an American shaver, indicating how deeply it has penetrated the American market.

In the early 1940s, the American company PHILCO registered "Philips" as a trademark due to the similarity in sound. Unable to use the company name "Philips," they used the initials of North American Philips [Electrical] Company to create the brand "Norelco," which continues to this day. The first shaver officially launched under the Norelco brand was the 1948 "IVORY." In 1951, they introduced the Double Header to the American market, but it was not very successful. A few years later, they renamed the same model "Speedshave," which significantly increased recognition and market share. Subsequently, they adopted new models and features such as the "Floating Head," "Flip-top Head," and the Three Header, focusing advertising on the Christmas sales season to increase market share. Recently, some products have used the Philips brand, but most Americans still think of Norelco as an American shaver, indicating how deeply it has penetrated the American market.